Verification and Validation of Equipment and Facilities

Release time:

2024-10-25

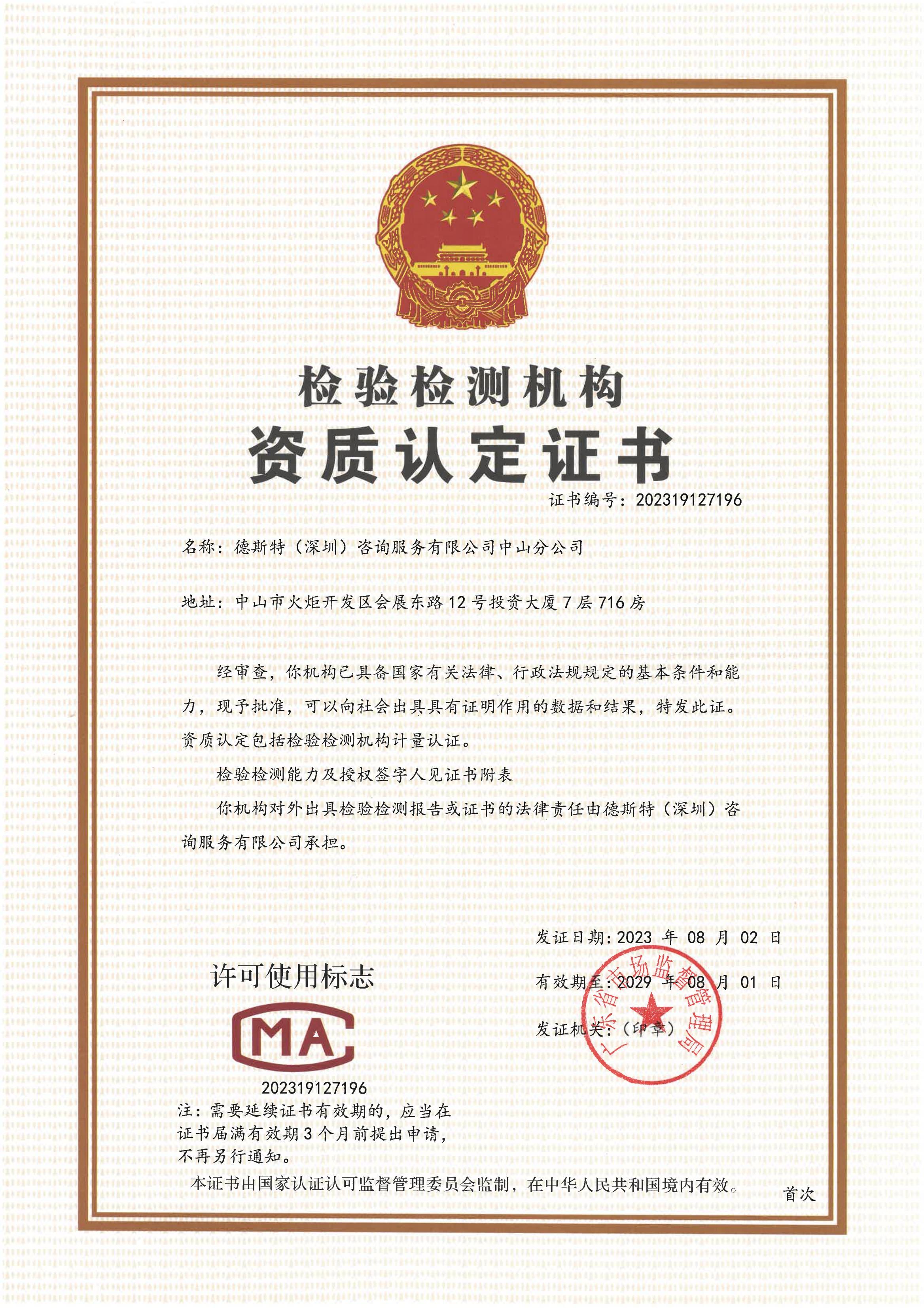

Durst has the CMA qualification of factory inspection. We provide the whole process guidance for factories, facilities and equipment suppliers in China and Europe and the United States, including verification training, assisting in drafting the verification master plan VMP, verification scheme VP, organizing the implementation and management of the whole process of verification (DQ, IQ, OQ, PQ), completing the verification report and evaluation and document standardization, specifically, it includes the verification of plant facilities and three major systems, equipment verification, cleaning verification, method verification, computer software system verification, process verification, etc., to ensure that the latest GMP requirements and global verification guidelines are met.

Durst has the CMA qualification of factory inspection. We provide the whole process guidance for factories, facilities and equipment suppliers in China and Europe and the United States, including verification training, assisting in drafting the verification master plan VMP, verification scheme VP, organizing the implementation and management of the whole process of verification (DQ, IQ, OQ, PQ), completing the verification report and evaluation and document standardization, specifically, it includes the verification of plant facilities and three major systems, equipment verification, cleaning verification, method verification, computer software system verification, process verification, etc., to ensure that the latest GMP requirements and global verification guidelines are met.

Facility Equipment Validation provides the following services:

1. Construction of plant verification system and system improvement consultation

Validation Protocol, Reporting Guidance and Enhancement:

Validate management system consultation (establishment or improvement).

Verify the establishment of key positions and personnel selection recommendations.

Based on the risk, formulate the establishment strategy of the verification management system to ensure compliance with the requirements of regulations or guidelines of China, FDA or EU, and close to the actual situation of the enterprise to ensure the efficient operation of the system.

Propose the document structure of the verification management system, draft/adjust the system document catalogue, and guide the enterprise or directly prepare the verification management system document. Or audit the existing verification system and guide the optimization of the system.

2. Verification scheme, report guidance and promotion:

Guide enterprises to draft URS documents, FAT, SAT, FS, DS, DQ, IQ, OQ, PQ plans, records and reports, and provide feasible rectification suggestions and guidance for different equipment to improve it to ensure that it meets the requirements of the target regulatory market.

3. Validation Test Services:

Can provide a complete verification test service, customized service plan according to enterprise needs, including verification plan drafting, verification risk assessment drafting, test execution, report drafting and deviation investigation in the verification process.

Provide professional verification and testing services, and provide necessary optimization suggestions according to the verification results or equipment conditions, and conduct systematic deviation investigation and treatment for deviations occurring during the test.

4. Verification Test Implementation Guidance

Provide on-site verification guidance, including new plant verification project management, verification test method training, verification implementation process supervision, verification process problem solving, etc;

Assist enterprises to train their own verification personnel, supervise the work of third-party testing services, etc.

Validation Items

Tunnel Oven Verification

|

|

● Filter outlet wind speed ● Differential pressure ● Cleanliness grade ● High efficiency filter leak detection ● Conveyor speed and temperature ● Load temperature distribution ● No-load temperature distribution ● Microbial challenge test ● Load heat penetration |

Incubator/Refrigerator Validation

● No-load temperature distribution ● Load temperature distribution ● Power failure challenge test ● Open Door Challenge Test |

|

Sterilization Cabinet Verification

|

|

●Air tightness test ● BD test ● No-load heat distribution test ● Full load heat distribution and heat penetration test ● Microbial challenge test ● SIP |

Rubber plug cleaning machine

● BD test ● Rubber plug cleaning effect (rubber plug moisture, visible foreign matter, insoluble particles, endotoxin) ● No-load heat distribution test ● Full load heat distribution and heat penetration test ● Microbial challenge test ● SIP |

|

Verification of Capping Machine

|

|

• Computerized system validation (security validation, emergency stop and power recovery validation, data integrity check, audit trail check, software • recovery test, system time accuracy validation) ● Noise confirmation ● Break bottle rate test ● Flow pattern test ● Production speed test ● Gapping effect test |

Filling Machine Validation

● Computerized system validation (security validation, emergency stop and power recovery validation, data integrity check, audit trail check, software recovery test, system time accuracy validation) ● Noise confirmation ● Break bottle rate test ● Flow pattern test ● Semi-plus plug test ● Online cleaning effect confirmation ● On-line sterilization procedure validation ● Production speed test ● Filling accuracy test |

|

Bottle washing machine verification

|

|

● Computerized system validation (security validation, emergency stop and power recovery validation, data integrity check, audit trail check, software recovery test, system time accuracy validation) ● Noise confirmation ● System moisture removal capacity check ● Confirmation of cleaning effect ● Inspection of bottle breakage rate |

Verification of dispensing system

● Online sterilization ● Cooling effect test of heat exchanger ● Weighing accuracy confirmation ● Confirmation of minimum mixing volume ● Mixing uniformity |

|

Pass Window Validation

|

|

● Installation confirmation ● Function confirmation ● Noise confirmation ● Interlock confirmation ● Illumination confirmation ● Timing confirmation ● Wind speed confirmation ● Airflow pattern ● Leakage of high efficiency filter ● Confirmation of the number of suspended particles |

Carbon dioxide shaker verification

● Panel function confirmation ● Noise confirmation ● Amplitude confirmation ● Speed confirmation ● Temperature confirmation ● Humidity confirmation ● Carbon dioxide confirmation ● Door opening test ● Limit value confirmation ● External irradiation intensity confirmation |

|

Liquid nitrogen tank verification

|

● Open cap test ● Confirmation of temperature distribution |

Laminar flow trolley, negative pressure weighing hood, clean bench, biological safety cabinet verification, FFU/RABS verification

● Illumination ● Airflow pattern ● Efficient leak pickup ● UV illumination ● Suspended particles ● Differential pressure ● Cleanliness level confirmation (floating bacteria, settling bacteria, surface bacteria) ● Wind speed ● Noise |

|

-Serviced customers-

Lizhu Pharmaceuticals, Yinowi, etc.

Next

Next:

Related Content

Plant design engineering construction management

Combined with the rich experience of the project team, the verification system and GMP system are optimized and improved according to the existing configuration and operation of the enterprise. Durst advocates the introduction of new verification ideas and concepts in Europe and the United States to promote project implementation:

2024-10-25

The formation of the quality of any drug is designed and produced, not tested. How to ensure that the quality of the product remains stable and high quality?

2024-10-25

Products registered in Europe and America

Durst (Delsalt) is a global pharmaceutical consulting company, maintaining exchanges and contacts with multiple industry associations in Europe and the United States. We have a wealth of global drug information resources, including solid oral preparations, injections, eye drops, and topical products. Durst has rich experience in the registration of products in developed countries such as the European Union and the United States, and has helped many pharmaceutical companies to complete the registration of products in the European Union and the United States. According to the needs of pharmaceutical companies, to help pharmaceutical companies through different ways to enter the developed European and American markets.

2024-10-25

European and American drug OEM

As a Spanish global consulting company, Delsalt has a wealth of product resources in Europe and the United States to meet the OEM needs of major customers in the current market. Entrusted processing (Original Equipment Manufacturer,OEM)& contract processing outsourcing (Contract Manufacture Organization,CMO): European drug listing license holding companies, entrusted to Chinese pharmaceutical enterprises production, entrusted companies to assist Chinese pharmaceutical enterprises to obtain EU GMP certification, production of drugs sold to the entrusted company, by the entrusted company sold to EU member states.

2024-10-25

New Drug Transfer in Europe and America

In countries such as Europe, the United States, Japan or India, their drug research and development technology is becoming more and more mature, and their research and development institutions have developed new drugs that are in the clinical stage or on the market. Through its resources in Europe and the United States, Delsalt can help companies obtain new drug transfer information from R & D institutions in the United States, Europe and Japan.

2024-10-25

QP Declaration of Conformity is a formal declaration of GMP conformity in the clinical phase of the product in the EU and PIC/S Member States, which has the effect of legal recognition, and the inspection in the clinical phase is equivalent to the official inspection. The QP shall be responsible for the GMP implementation results of the enterprise. In the clinical phase, the QP conformity statement can be submitted as GMP conformity data in the clinical phase to the EU or PIC/S countries as the basis for GMP conformity. The QP declaration of conformity is also a very good proof of compliance before the enterprise has not obtained the official GMP certificate overseas. According to the EU QP regulation, except in special circumstances, the QP declaration of conformity needs to be checked remotely, the enterprise or local government provides proof, and the QP should go to the site for review.

2024-10-25